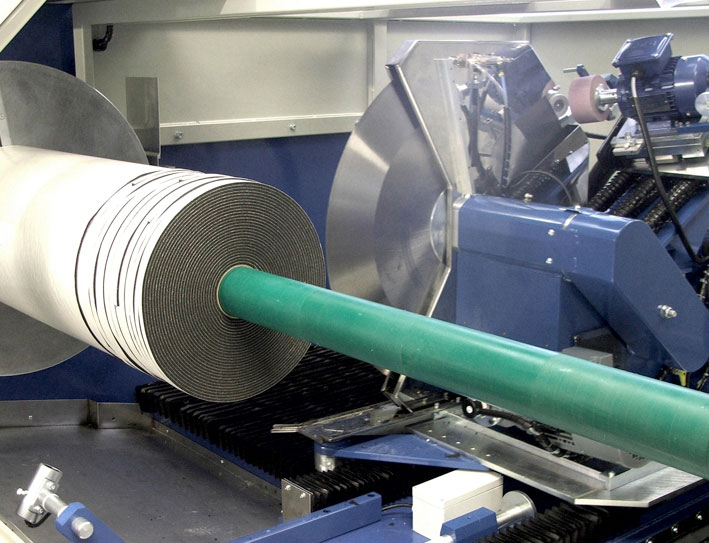

Roll Slitting

Premier Gaskets incorporates multiple slitting processes capable of precisely slitting most soft to semi-rigid rolled materials. Roll slitting is the process of cutting a roll (or log) of material into two or more narrower widths. Roll Slitters (also called log slitters or baloney slicers) use a single, large circular blade to cut all the way through a roll of material, which is typically on a 3″ paper or plastic core. As the machine brings the blade against the roll of material, which is rotating at 400-500 rpm on the mandrel/shaft, the blade cuts through the material and core in just a few seconds. Roll slitters are used for a wide variety of applications. These cutting systems are capable of slitting materials such as pressure sensitive tapes, foams, foils, films, textiles, nonwovens, rubber, felt, cork and paper. Our machine slitting capacities go up to 60″ width and 16″ diameter rolls.