Die Cutting and Kiss Cutting

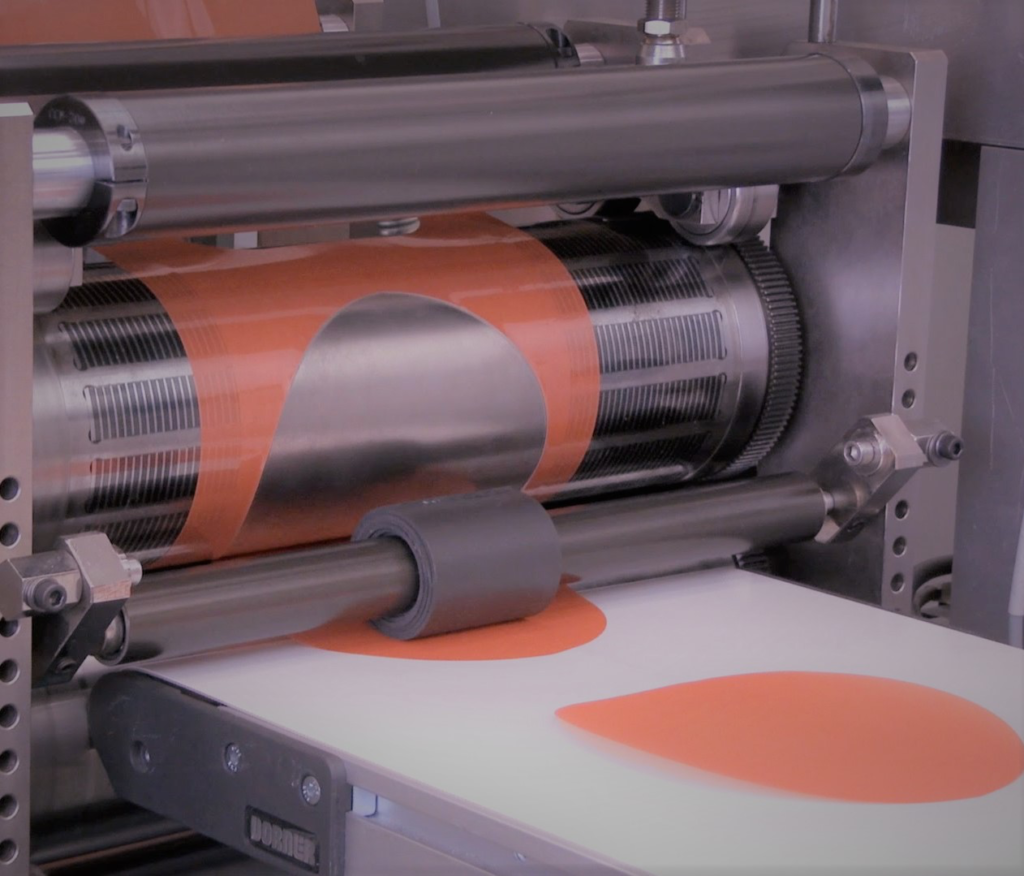

Premier Gaskets specializes in high-speed, high-volume rotary die cutting. We also use punch presses and clicker presses for smaller volume applications.

Premier Gaskets offers die cutting services in order to fabricate products to unique client requirements. Premier Gaskets is able to meet the die cutting requirements of a wide range of industries and applications. While our primary specialty is die cut gaskets, we can also provide services on many other die cut shapes with various materials.

Die cutting is the precise fabrication or conversion of selected materials into sheet or roll forms in the desired shape and size. Premier Gaskets is ready to assist with the creation of custom gaskets that meet the exact needs of your upcoming project from engineering to final delivery.

Die cutting is performed by means of die cutting machines such as a press or a rotary die, and is used to cut a two-dimensional product out of a flat sheet of material. Premier Gaskets is a top-of-the-line die cutter ready to serve your needs with four different types of presses.

Kiss Cutting is also available. In this process, the die cuts through the material and backing (adhesive) as to form the gasket, but does not cut through the paper backing. By using this precision cutting, the end user is enabled to easily peel and stick the product to the desired location while keeping the material in a neatly organized fashion.